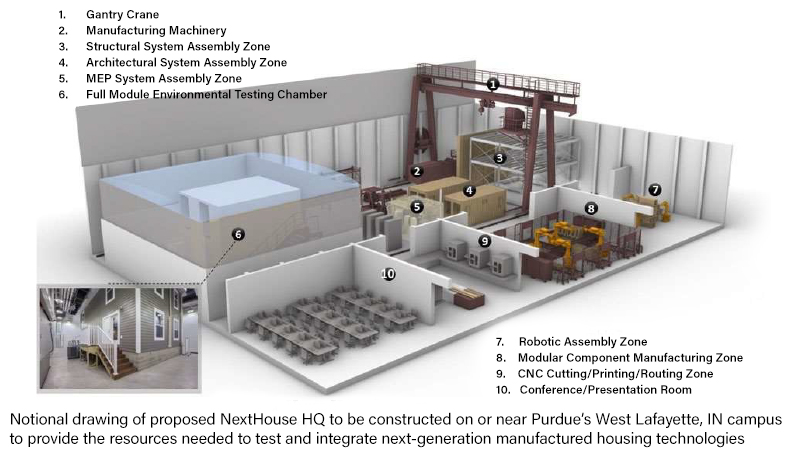

At the heart of NextHouse’s innovation is a network of state-of-the-art facilities designed to enable cutting-edge research, prototyping, and workforce training. The upcoming NextHouse Headquarters, located near Purdue University in West Lafayette, Indiana, will serve as a hub for advanced modular housing technology development. This facility will feature capabilities like climate-controlled testing chambers, prototyping labs, and automation testbeds, all designed to accelerate the deployment of next-generation housing solutions.

Purdue University

West Lafayette, IN

Purdue University is a driving force behind the NextHouse initiative, leveraging its expertise in advanced manufacturing, automation, and sustainable construction to transform the future of modular housing. Central to Purdue’s involvement is the development of the NextHouse Headquarters (HQ) in West Lafayette, Indiana, a state-of-the-art facility designed for prototyping, testing, and training. This HQ will feature climate-controlled testing environments, automation testbeds, and collaborative research spaces where industry partners, policymakers, and academics can refine and commercialize modular housing innovations. With Purdue’s Institute for Innovation Science guiding research in materials science, robotics, and industrial automation, NextHouse will integrate AI-driven collaborative robots, lean manufacturing processes, and next-generation building materials to improve efficiency, affordability, and sustainability in housing production.

Founded in 1957, the Ray W. Herrick Laboratories supports world-class Mechanical Engineering research for students, faculty, and industry. Among the facilities available in our 83,000 square feet of space are HVAC and indoor air quality labs; advanced engine test cells; acoustics, noise, and vibration testing; and unique perception-based engineering labs. Herrick is also home to the Center for High Performance Buildings, which partners with industry to develop new technologies in sustainable building systems, indoor environments, human perception and comfort, and high performance equipment.

Michigan State University

East Lansing, MI

At Michigan State University (MSU), the Engine will access the Construction Management Education and Research Laboratory to investigate the modular housing assembly. The facility is an approximately 4,500 sq.ft. high-bay space with a suite of modem construction tools, material and tool storage, assembly/building space, movable tables/chairs, and an LCD projector and screen.

A supplemental Building Information Modeling laboratory is being constructed adjacent to the existing laboratory facility. This space will provide dedicated PC, software, and virtual/augmented reality hardware access to faculty and students. In addition, the School of Planning, Design & Construction features two construction- and design-specific computer laboratories that will be available with specific software such as construction estimating and scheduling, 2D, 3D, and 5D+ computer-aided drafting (BIM), and SPSS (statistical analysis). As part of the research activities, in-depth analyses of construction materials will be carried out.

To this end, relevant laboratory equipment includes:

- three gas-controlled chambers (with microplate reader and incubators),

- five gas stations with gas transfer ports (CO2, N2, N2:CO2 and H2), and 20-channel manifolds for media preparation;

- a Varian 660-IR FT-IR spectrometer,

- light and phase-contrast/fluorescence microscopes,

- one Chemchek Kinetic Phosphorescence Analyzer (KPA),

- molecular biology space and equipment (e.g., master cyclers, electroporators, biophotometer, Labconco HEPA-filtered PCR enclosure, fully equipped benchwork area for nucleic acid and protein electrophoresis),

- a Beckman HPLC with UV detector,

- autosampler and integrator,

- a Varian micro-GC with flame ionization andthermal conductivity detectors, and

- fully equipped media room.

University of Notre Dame

South Bend, IN

The University of Notre Dame is a key partner in the NextHouse initiative, contributing cutting-edge research, workforce development programs, and interdisciplinary expertise to drive innovation in modular housing. Notre Dame’s extensive facilities and institutes provide critical support for advancing sustainable design, policy development, and social impact strategies that align with NextHouse’s mission to transform factory-built housing.

The Fitzgerald Institute for Real Estate plays a pivotal role in shaping policy frameworks and financing strategies for modular housing, ensuring that NextHouse solutions are economically viable and scalable. Complementing this, the Michael Christopher Duda Center for Preservation, Resilience, and Sustainability focuses on developing long-term sustainability strategies, integrating resilient materials, and preserving affordability within housing ecosystems. Meanwhile, Notre Dame Energy provides essential research on energy-efficient building systems, exploring innovations in grid-responsive homes, renewable energy integration, and climate-conscious housing solutions.

Beyond technological advancements, NextHouse is committed to community engagement and workforce training. The Pulte Institute for Global Development and the Institute for Social Concerns are instrumental in addressing housing equity, policy reform, and community-based initiatives, ensuring that NextHouse solutions meet the needs of underserved populations. The Center for Broader Impacts further enhances these efforts by fostering partnerships that connect research to real-world applications, amplifying the societal reach of NextHouse innovations.

Innovation and entrepreneurship are also central to NextHouse’s success. The Idea Center serves as a launchpad for commercializing new housing technologies, helping translate academic research into market-ready solutions. By fostering collaboration between students, faculty, and industry leaders, the Idea Center accelerates the deployment of modular housing innovations. Collectively, these Notre Dame facilities provide an interdisciplinary foundation for NextHouse, advancing the development, implementation, and adoption of sustainable, affordable housing at scale.

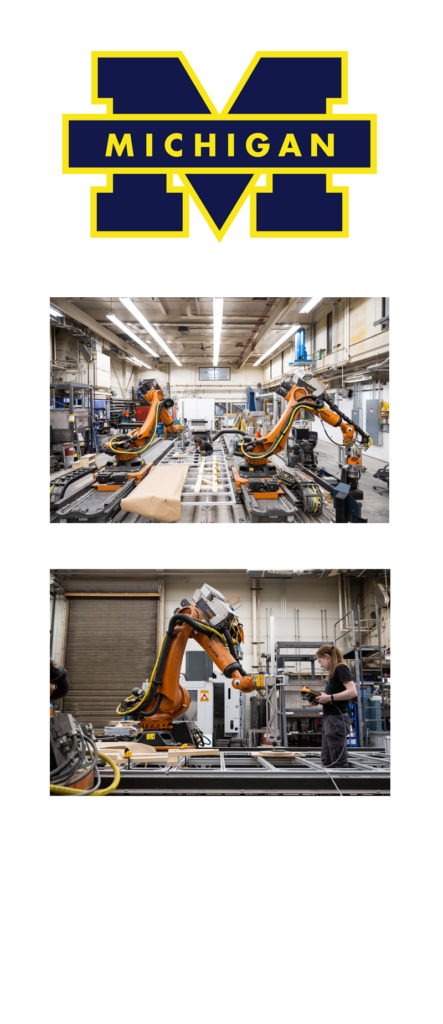

University of Michigan

Ann Arbor, MI

The University of Michigan’s Taubman College of Architecture and Urban Planning in Ann Arbor will be a vital component of the NextHouse project, premier architectural manufacturing research lab in North America and one of a few select academic labs performing both subtractive and additive manufacturing processes utilizing robotic automation.

The Fabrication Lab offers 10,000 square feet of high-bay research space and leverages state-of-the-art equipment including industrial robots, CNC machines, digital prototyping tools, and fully outfitted wood and metal shop spaces to support prototyping, fabrication, and assembly. Enabling a core focus on robotic applications in construction and architectural fabrication, the lab’s industrial robots are organized into cooperative work cells connected with a real-time industrial network to facilitate online control of the system. The lab is designed to support customized fabrication for robotics and offers a range of tooling components.

The equipment available to the project team will include:

- Robotics

- CNC

- Rapid Prototyping

- Fabrication

In addition to these Taubman College resources, the research team will have access to advanced computing, secure data storage, an extensive array of software, and video conferencing capabilities through U-M’s central Information and Technology Services.